Plant Products

Air separation plants produce oxygen, nitrogen and argon from atmospheric air, normally by one of two processes: cryogenic or non-cryogenic. Non-cryogenic plants produce oxygen or nitrogen gas product from compressed air at near ambient temperature by physical adsorption. Non-cryogenic plants can be a cost effective alternative where a single gas only product (either oxygen or nitrogen) is required, the production is relatively low and high purity is not required. Cryogenic plants liquefy and distill ambient air to separate it into its components. Cryogenic plants can produce either high production rates of gas and/or liquid products (oxygen, nitrogen and argon) at high purity levels.

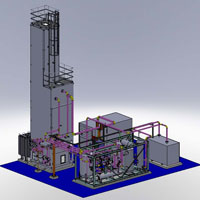

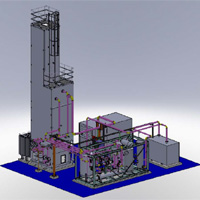

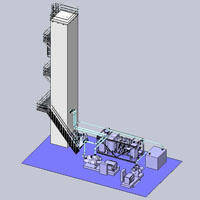

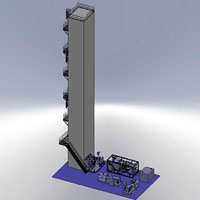

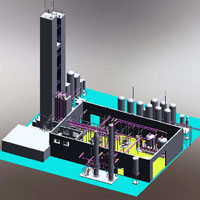

Modular plant packaging minimizes the scope of on-site installation work thus maximizing the overall quality level of the plant installation and minimizing total project cost, project cycle time and required in-site construction resources.

Standard purity levels are 99.6% pure oxygen product, 2 PPM maximum oxygen in nitrogen product, 99.999% pure argon product. Higher purity levels are available in certain process configurations. Plant control can be manual or completely automated with remote access capability.

-

Merchant Liquid Plants

Oxygen and nitrogen production, with and without argon production.

- Up to 6000 Nm3/hr of production

- Ultra-low specific power consumption

- Optional UHP nitrogen (99.9999%) and/or UHP oxygen (99.995%) capability

-

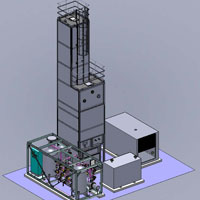

On-site Oxygen Gas Generators

- Up to 6000 Nm3/hr of GOX production

- GOX or GOX + GAN

- Optional argon production

- Cost of delivered gas is much less than bulk liquid product

-

On-site Nitrogen Gas Generators

- From 400 to 6000 NM3/hr of production

- Available in Liquid assist or self-refrigerated configuration

- Completely prepackaged for quick and easy installation

- Cost of delivered gas is much less than bulk liquid nitrogen

-

Containerized and Container-Transportable LOX/LIN Generators

- Up to 200 Nm3/hr of production

- Manual or fully automated control

- Available air cooled configuration minimizes required utilities (power only)

-

Options and Plant Accessories

- Product liquefiers

- Gas cylinder filling systems